COMMERCIAL AND INDUSTRIAL COLD ROOMS

Our company designs and constructs a wide range of cold rooms in accordance with the European standard “ETA 10/0001”, for various purposes and capacities – from small refrigeration rooms to large-scale facilities for the food industry. Depending on their intended use, all cold rooms are designed and built for different applications, fully complying with HACCP standards.

![]()

Cold rooms (TN) for fresh products are used to preserve the freshness of products over extended periods while maintaining product quality and preventing deterioration of their external appearance. Depending on the type of product and the storage requirements, they are maintained at different temperature ranges, as indicated in food technology literature. The temperature range -5°C to +8°C is one of the most common for cold storage facilities. Critical temperature levels are determined based on the type of product to be stored.

We build refrigeration cold rooms for a wide variety of products, including:

Fruits & Vegetables

Meat & Cheese

Fish

Flowers & Other Plants

Milk & Dairy Products

Desserts & Chocolate

![]()

Freezing Cold Rooms (BT) are designed for rapid freezing and storage of products. Initially, cold storage rooms for frozen products are essential to maintain product stability and extend shelf life, as freezing prevents microbial growth. Freezing storage facilities, also known as freezer rooms, are typically used for products stored at temperatures between -18°C and -21°C, except for ice cream, which is stored at -25°C. At these temperatures, microbial growth is completely halted, while enzymatic and non-enzymatic changes continue at a very slow rate.

Food products are first frozen in specialized blast freezing rooms, operating at temperatures between -32°C and -40°C. Blast freezing is a process in which the product is cooled rapidly until its core temperature reaches -18°C, after which the products are transferred to the storage freezer rooms.

To select the appropriate refrigeration equipment, it is necessary to gather information about the type of product, quantity, inlet temperature, room dimensions, and the desired blast freezing time, in order to accurately calculate the refrigeration load. Our team includes experienced engineers, providing efficient and professional solutions to ensure that food products are stored safely and hygienically.

The freezing and storage cold rooms built by our company can be used for a wide range of products, including:

Ice Cream

Meat & Meat Products

Dough & Bakery Products

Fruits & Vegetables

![]()

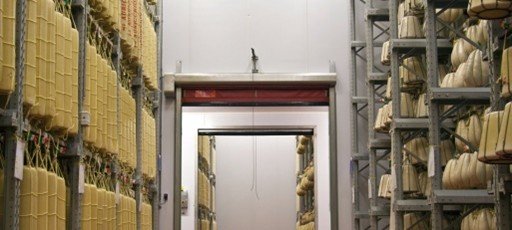

Rooms for Drying, Smoking, Maturation, and Cultivation of Products

Our company also designs and constructs specialized rooms for drying, smoking, maturation, and cultivation of products, tailored to the type of product and its processing requirements. These rooms are fully harmonized with the technological production schedule, based on design parameters for air quality (temperature, humidity, airflow, and air composition) in real time.

Our drying, maturation, and smoking systems for cured meats are equipped with enthalpy-based functional devices (allowing intelligent use of outside air), clean rooms for packaging, high-quality materials, and a high level of hygiene, all designed for easy cleaning and maintenance, supported by our Italian partners.

All systems are computerized, with customizable cycles and recipes, and allow detailed recording of thermo-hygrometric parameters.

These rooms are used for processing and cultivating various products, including:

Drying and curing of meats

Maturation (Aging) of cheeses

Cultivation and sprouting of plants

![]()

Cold and Neutral Processing Rooms

Cold and neutral processing rooms include areas for product processing, packaging, and transportation, where cooling is required to maintain the cold chain. The recommended temperature for these zones is between +12°C and +16°C.

An important factor to consider during the planning of these rooms is the health and comfort of the staff working in these areas. The airflow and noise generated by the internal cooling units must not negatively affect the comfort of the workers.

We ensure the optimal climate in these zones, paying special attention to both human health and food safety.